Rickinghall is our original base and is still the home of the Engineering team along with all the fabrication shops, storage as well as being the home of the finance team, the design/drawing office, compliance and HR.

Stainless steel and aluminium manufacturing facility

We have an 8,000 ft2 stainless steel and aluminium fabrication facility with milling and turning capabilities. This workshop is home to a four-metre 250 tonne brake press and 4m x 16mm guillotine.

This is where most of our food processing and refrigeration work takes place. It is large enough to allow us to construct and pre-fit what we will install in clients’ facilities so that we minimise any disruption on site during its installation.

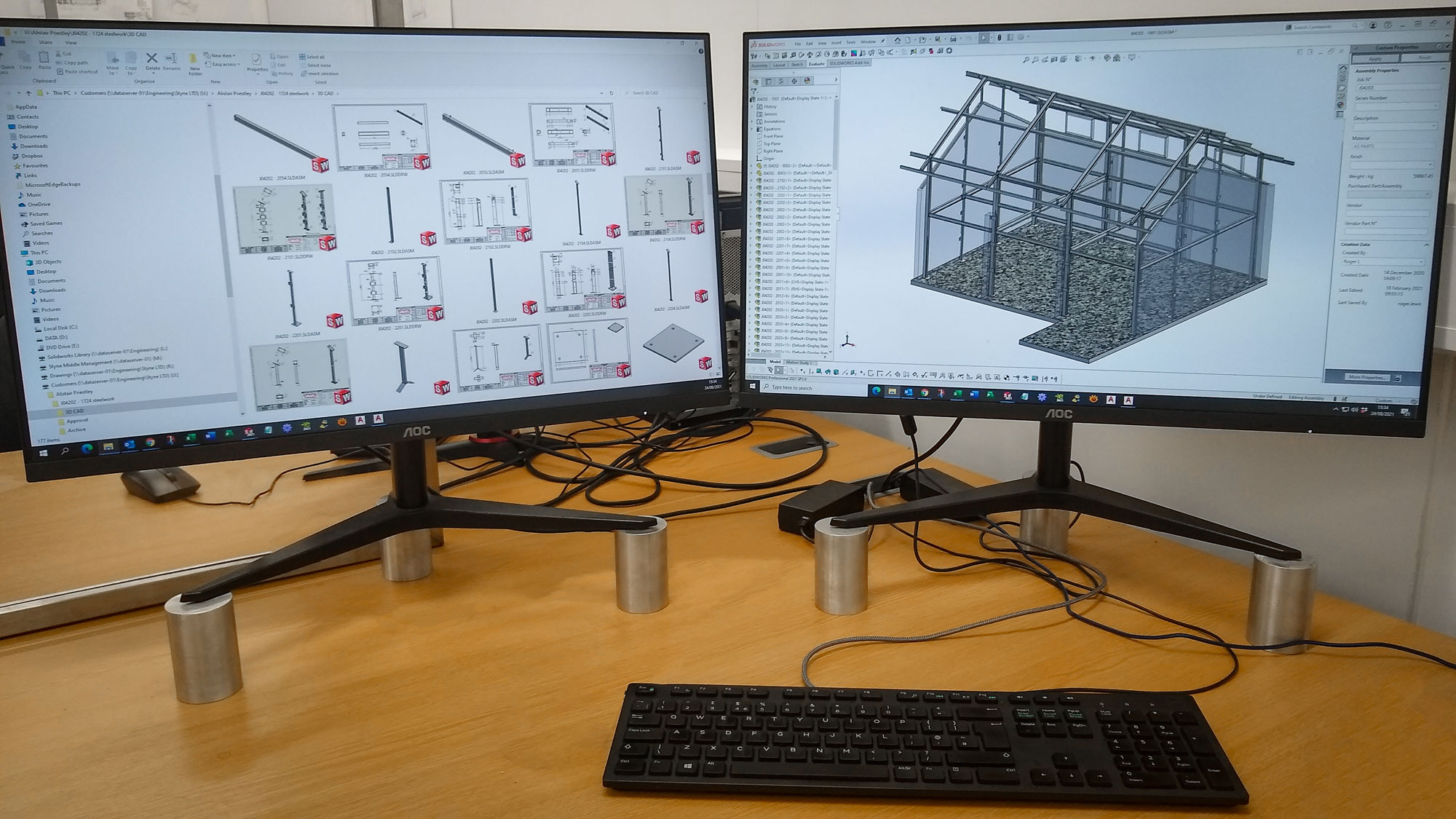

Mild steel manufacturing facility

In addition, we have a 2,300 ft² mild steel manufacturing facility where we fabricate structural steel work to comply with the BS EN1090 factory production control standard.

This is where we manufacture gantries and platforms, mezzanine floors, CAT ladders and spiral staircases, portal frame buildings and structural steelwork.

This facility also includes a finishing plant where we can galvanize, powder coat or paint the mild steel structures to give a high quality and durable finish.